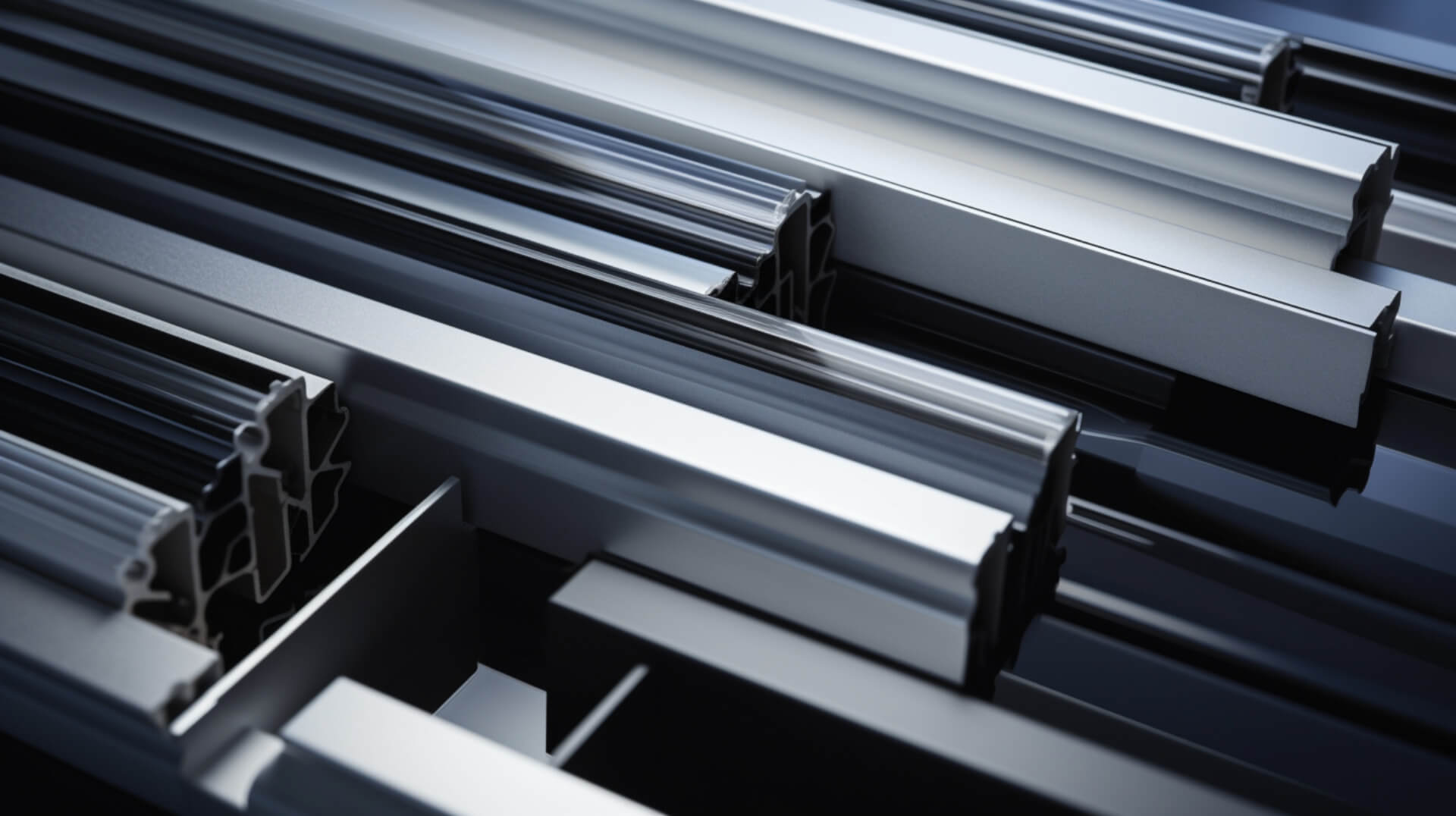

Although aluminum joinery systems are preferred for their durability and aesthetic features, they require maintenance at certain intervals to ensure their longevity. Aluminum joinery affected by sun, wind, rain and temperature changes may lose performance over time. Therefore, periodic maintenance and repair operations are important for joinery to maintain their first-day performance. Regular maintenance increases energy efficiency, preserves their aesthetic appearance and prevents larger repair costs in the long run.

1. Importance of Periodic Maintenance

Periodic maintenance of aluminum joinery systems preserves the insulation performance, functionality and appearance of the structure. The advantages of maintenance include energy efficiency, sealing and making the system more durable.

Energy Efficiency: In aluminum joinery, gaskets and insulation materials may wear out over time. In this case, more energy is spent to maintain the temperature of the interior. Regular maintenance keeps the energy efficiency of joinery high.

Sealing: The hinges and seals of joinery may lose their flexibility over time, which may cause wind, dust and moisture to leak inside. During maintenance, worn parts are replaced to ensure sealing.

Aesthetic Appearance: External factors may cause dulling or color changes on aluminum surfaces. The aesthetic appearance of joinery is preserved for a long time with surface cleaning and protection processes.

2. Cleaning and Maintenance Techniques

Regular cleaning of aluminum joinery systems helps the joinery maintain its visual innovation and extend its service life. These cleaning processes are especially important for joinery exposed to the exterior.

Regular Cleaning: Cleaning aluminum joinery prevents dirt and stains caused by the accumulation of external factors. pH-balanced soaps and a soft cloth should be used during cleaning. Abrasive detergents or hard sponges may damage the surface of the joinery.

Dust and Dirt Cleaning: Dust, especially accumulated on windows, can block the hinge and rail parts of the joinery, making it difficult to open and close. Dust and dirt accumulations should be cleaned with soft brushes or low-pressure water.

Using Surface Protector: Aluminum joinery can be coated with a protective coating. These coatings prevent the joinery from scratching and rusting. Protective coatings are especially important in structures by the sea.

3. Lubrication of Moving Parts

Hinge, lock and rail systems in door and window joinery can become jammed or lose their function over time. Lubricating these parts to maintain their functionality allows the joinery to open and close more easily.

Hinge and Lock Lubrication: Moving parts such as hinges and locks should be lubricated with special oils at certain intervals. This process reduces the wear of the parts caused by friction and ensures silent operation.

Rail System Maintenance: The rails in sliding door and window systems should be cleaned and lubricated. Dust and dirt accumulated in the rail system can increase friction and cause the joinery to move with difficulty.

4. Checking the Sealing and Insulation Elements

Elements such as gaskets and wicks that provide the insulation and sealing performance of joinery may wear out over time and become incapable of fulfilling their duties. Renewal of these worn parts preserves the heat and sound insulation properties of joinery.

Gasket and Wick Replacement: Gaskets and wicks, which have a flexible structure, may crack or lose their flexibility due to temperature changes. Worn gaskets are replaced with new ones to ensure the sealing of the joinery.

Corner and Edge Checks: Sealing checks should be performed in the corner and edge areas of joinery. Openings in these areas may negatively affect the functionality and insulation properties of joinery.

5. Renewal of Surface Coatings

Aluminum joinery is generally protected with anodized or electrostatic paint coatings. However, over time, these coatings may lose their resistance to factors such as sunlight, rain and wind. Coating renewal processes increase the surface durability of joinery.

Anodized Coating Maintenance: Aluminum joinery is protected against rust with anodized coating. This coating, which wears out over time, is reapplied to protect the surface of the joinery.

Electrostatic Paint Renewal: If there is scratching or abrasion on the joinery surfaces, an electrostatic paint renewal process can be performed. This process restores the aesthetic appearance of the joinery.

6. Repair and Replacement of Damaged Parts

Depending on the intensity of use, some parts may be damaged or lose their function. In this case, repair operations or part replacement may be required.

Hinge and Lock Replacement: When moving parts such as hinges or locks are broken or jammed, they should be replaced. If repair of these parts is not possible, they are replaced with new ones